high strength low alloy steel tubing

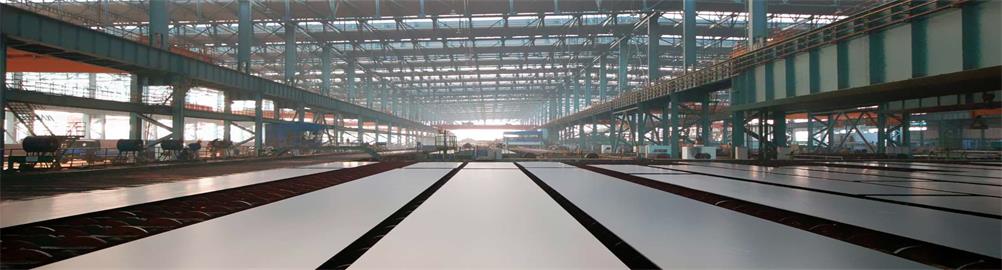

High-strength low-alloy steel pipe

High-strength low-alloy steel (HSLA) pipe is like a shot in the arm for ordinary steel. Just a little bit of special elements, such as niobium or vanadium (less than 0.15%), can make it 30% to 50% stronger than ordinary steel. Moreover, it has good welding performance and is more resistant to corrosion. Therefore, it can be found in the skeletons of skyscrapers and oil and gas pipelines.

Why is it so strong?

The magic of microalloying: trace elements such as niobium and vanadium are like "little bodyguards". They make the grains (internal small structures) of steel finer and denser during the manufacturing process. This makes the pipe particularly impact-resistant and can maintain toughness (impact energy can reach 60 joules) even at -40°C (like the Arctic), which is crucial for pipes.

Thermo-mechanically controlled process (TMCP): This is not the old-fashioned heat treatment. It "locks" the optimized internal structure of the steel by precisely controlling the rolling temperature and cooling rate, without the need for expensive quenching.

Self-contained anti-rust layer: Some grades add copper and phosphorus to form a protective film. The result? In an industrial environment, it rusts at a rate of only 0.025 mm per year, while ordinary steel (low-carbon steel) rusts 0.2 mm.

Where does it play a major role?

The tough guy in the structural world (such as ASTM A500):

Why do engineers love it? ** High strength (yield strength 460 MPa), but 20% lighter than ordinary carbon steel.

Real skill: The seismic support of the Shanghai Tower uses it and successfully withstands the test of simulating a magnitude 9 earthquake.

The backbone of the energy industry (such as API 5L X70):

The king of pressure resistance: It can withstand high pressures of more than 300 bar, and gas pipelines like "Nord Stream" use it.

Acid resistance expert: In oil fields with high sulfur content (hydrogen sulfide), ordinary steel is easy to crack, but it can withstand (resistance to hydrogen-induced cracking).

Innovator in the field of transportation (such as SAE J2340):

Energy absorber: It can absorb a lot of impact energy (40 kJ) in a collision to protect safety. Tesla electric car battery pack shell relies on it.

Weight reduction expert: Using it as a body frame can reduce weight by 15%, allowing electric vehicles to run 7% more distance.

Compare with other materials

Compared with ordinary carbon steel: 50% higher strength, only 20%-40% more expensive (per kilogram). But because it is more durable and uses less materials, the total cost for 20 years can be saved by 50%.

Compared with aluminum: much higher stiffness (210 GPa vs 69 GPa). Choose it where it needs to be particularly stiff and not deformed.

Compared with stainless steel (type 304): The price is about half cheaper. If the corrosion environment is not particularly harsh, it is more cost-effective to use it.

Tips for use

Welding: Control the "carbon equivalent" (a measure of welding difficulty) and do not exceed 0.25%. Before welding thick pipes (>25 mm), preheat to about 120℃ to avoid cracks.

Bending: The bending radius should not be less than 3 times the diameter of the pipe. It is best to use a mandrel to support the pipe when bending to prevent it from being flattened and deformed.

Rust prevention: In industrial areas or ordinary urban environments, choose "weathering steel" grades. Its built-in protective film is more effective than paint! Only in strong acid environments (pH<4) do you need additional galvanizing to prevent rust.

Sentence summary

High-strength low-alloy steel pipes are a model of metallurgical technology solving practical engineering problems. It is not cheap ordinary steel, but a precision-designed engineering material used in critical situations where "failure is absolutely not allowed." If you choose it right, you can build a strong structure that will last longer than the designer.